Key Components of a Robust Supply Chain Security Audit

Identifying Vulnerabilities in Third-Party Suppliers

A critical aspect of any supply chain security audit involves carefully pinpointing weaknesses among third-party suppliers. This requires a detailed evaluation of their security measures, including policies, procedures, and technological safeguards. Going beyond paperwork, this process should incorporate on-site inspections, discussions with key staff, and even simulated attacks to uncover hidden risks. Such thorough vetting is vital to minimize dangers tied to external dependencies in your supply chain.

Since suppliers operate in varied settings, the audit must adjust to differing security standards. A flexible yet standardized approach ensures no critical gaps are missed, regardless of a supplier's size or location. This adaptability guarantees each supplier's unique risks are properly addressed.

Assessing the Security of Inventory and Materials

Protecting raw materials, unfinished goods, and final products is fundamental to supply chain security. Audits must scrutinize inventory management practices, including physical security, access restrictions, and tracking systems. Special attention should focus on safeguarding sensitive items with intellectual property or regulatory requirements. The audit should also outline clear steps for handling security breaches within inventory systems.

Evaluating Transportation and Logistics Security

Transport networks represent significant weak points in supply chains. A comprehensive audit examines vehicle security, cargo handling methods, and protection for data transmitted during shipping. Particular emphasis should be placed on third-party logistics providers' security measures, addressing risks like theft, tampering, or data leaks during transit.

Analyzing Internal Controls and Processes

Internal procedures form the backbone of supply chain integrity. Security audits must review how goods are received, stored, processed, and distributed internally. This includes examining staff access privileges, data protection methods, and employee security awareness. The goal is to spot and fix any process gaps that might expose the supply chain to threats.

Reviewing Security Policies and Procedures

Effective audits thoroughly examine both your organization's and suppliers' security policies. The evaluation should assess current policies' effectiveness, identify shortcomings, and suggest enhancements to ensure compliance with industry standards and regulations across the entire supply network.

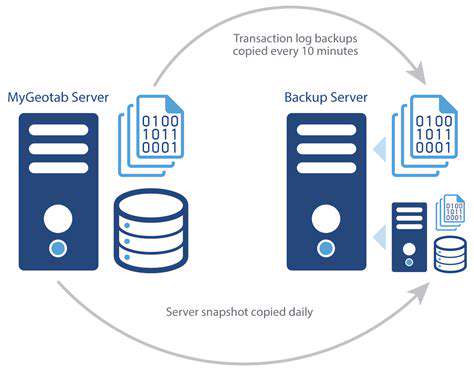

Implementing and Maintaining Security Improvements

The most crucial audit phase involves putting identified security upgrades into practice and ensuring their continued effectiveness. This requires developing specific solutions for vulnerabilities and integrating them seamlessly into daily operations. Strong communication between auditors, management, and relevant departments is essential. Ongoing monitoring programs help maintain these security measures long-term, bolstering the supply chain's defense against potential threats.

Measuring the Impact and Continuous Improvement

Understanding the Importance of Impact Measurement

Measuring audit impact proves their worth and justifies the investment. Beyond finding weaknesses, this involves quantifying mitigated risks, cost savings from early problem detection, and overall supply chain strength improvements. This data-centric method helps demonstrate audit benefits to stakeholders, promoting proactive security culture.

Connecting audit findings to potential business interruptions is crucial. For example, if a supplier's security flaw is discovered, assessing possible financial and reputational harm from a breach helps prioritize fixes and allocate resources wisely.

Implementing Continuous Improvement Strategies

Supply chain security enhancement is an endless cycle requiring constant attention. Establishing clear metrics for security incidents, vulnerability fixes, and supplier compliance allows organizations to spot improvement areas and adjust audit tactics.

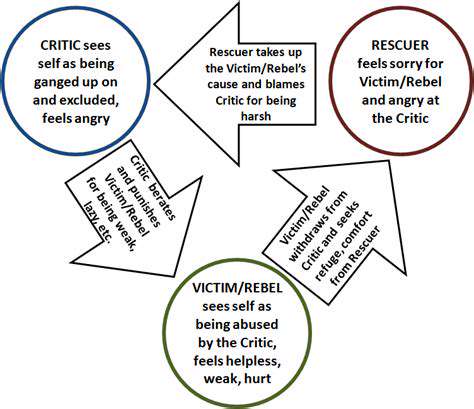

Creating cooperation between internal teams (like procurement and risk management) and external partners (such as suppliers) ensures everyone values supply chain security. Open communication and regular feedback drive ongoing improvements and adaptation to new threats.

Updating audit methods to counter emerging risks is equally important. As global supply chains evolve, audit approaches must incorporate new threats, past lessons, and industry best practices to remain effective.

Establishing a Framework for Ongoing Assessment

A solid framework for evaluating audit effectiveness should include guidelines for frequency, scope, and methods, applied consistently across all supply chain levels. Clear supplier performance criteria ensure fair, uniform evaluations.

Regular framework reviews allow adjustments for new threats and past audit insights. This flexible approach keeps the audit program relevant and capable of protecting organizational interests and supply chain integrity.