Understanding the Human Element

Resilient supply chains aren't built solely on sophisticated software or intricate logistics networks. A crucial component often overlooked is the human element. Cultivating a culture of resilience within your organization means fostering a mindset that embraces challenges, adapts to disruptions, and proactively seeks solutions. This includes empowering employees at all levels to identify potential risks and contribute to mitigation strategies. A strong company culture, where communication is open and collaboration is valued, is paramount to navigating uncertainty and bouncing back from setbacks.

Investing in training and development programs that equip employees with the skills to handle unexpected events, such as communication protocols during crises and problem-solving techniques, can greatly enhance their ability to contribute to the overall resilience of the supply chain. Furthermore, recognition and reward systems that acknowledge proactive measures and effective responses to risks can further incentivize a culture of resilience.

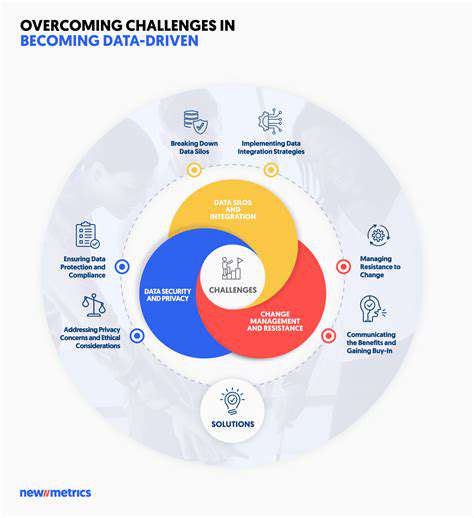

Proactive Risk Identification and Mitigation

Simply reacting to disruptions is insufficient. A truly resilient supply chain proactively identifies potential risks, analyzes their likelihood and impact, and implements mitigation strategies before a crisis hits. This involves a comprehensive review of all supply chain partners and processes, identifying vulnerabilities, and developing contingency plans. Regular risk assessments are essential for staying ahead of potential issues and adapting to emerging threats.

Regularly updating these assessments based on market shifts, geopolitical events, and technological advancements is vital. A robust risk management system should encompass various perspectives, including financial, operational, and environmental factors, to ensure a holistic view of potential disruptions. This proactive approach allows your organization to adapt and adjust its strategies in response to unforeseen events with minimal disruption.

Building Strong Supplier Relationships

Supply chain resilience is deeply intertwined with the strength of relationships with suppliers. Building trust and fostering open communication with key suppliers is crucial. This involves more than just transactional agreements; it's about understanding their operations, challenges, and potential vulnerabilities. Collaborative problem-solving and shared responsibility for risk mitigation are key elements of strong supplier relationships.

Diversifying your supplier base, where feasible, can reduce reliance on a single source and minimize the impact of disruptions affecting a single supplier. Long-term partnerships built on mutual respect and understanding are essential to navigating periods of uncertainty and ensuring a consistent flow of goods and services.

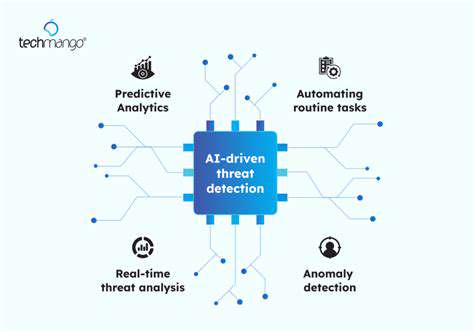

Embracing Technology for Enhanced Visibility

Technology plays a significant role in building a resilient supply chain. Implementing advanced tracking and monitoring systems provides real-time visibility into the movement of goods, allowing for quicker identification of bottlenecks and delays. Data analytics can further assist in identifying patterns and predicting potential disruptions, giving the organization a crucial head start in responding to emerging challenges.

Leveraging digital platforms for communication and collaboration among different stakeholders across the supply chain streamlines processes and improves coordination during times of crisis. Investing in robust technology infrastructure that facilitates these processes is essential for enhancing the overall resilience of the supply chain. This involves not only the technology itself but also the training and support necessary for effective implementation.

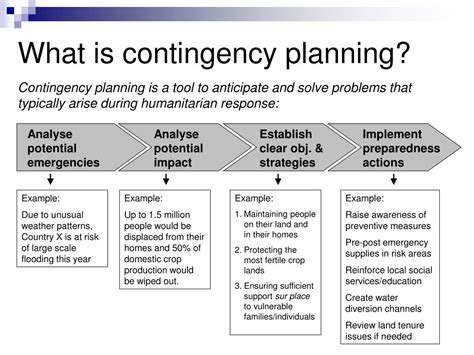

Developing Contingency Plans and Crisis Response Protocols

A critical aspect of building a resilient supply chain is the development of comprehensive contingency plans and well-defined crisis response protocols. These plans should outline specific procedures for handling various potential disruptions, including natural disasters, geopolitical instability, and pandemics. The plans should be regularly tested and updated to ensure their effectiveness and relevance in a dynamic environment.

Establishing clear communication channels and roles during a crisis is essential. Regular training exercises for key personnel on how to execute these plans are paramount to ensuring a smooth and effective response when disruptions occur. This proactive approach ensures a more rapid and organized recovery process, minimizing the impact of any unforeseen event on the supply chain.