The Rise of Edge Computing in IIoT

Edge computing is fundamentally transforming Industrial IoT operations by decentralizing data processing. This architectural shift dramatically reduces latency, enabling near-instantaneous response to operational events while improving overall system performance. Modern edge devices now possess enhanced processing capabilities, allowing autonomous decision-making without cloud dependency, resulting in more responsive and resilient industrial systems.

This distributed computing model also improves data security by limiting exposure of sensitive information during transmission. Localized data processing helps organizations comply with stringent data protection regulations while reducing attack surfaces.

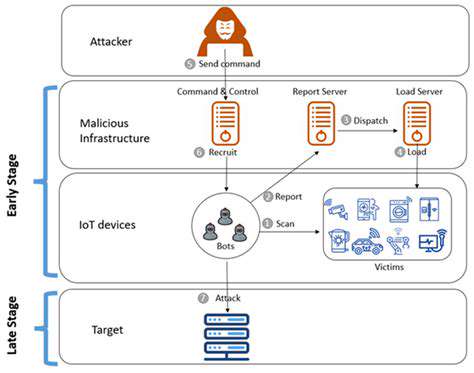

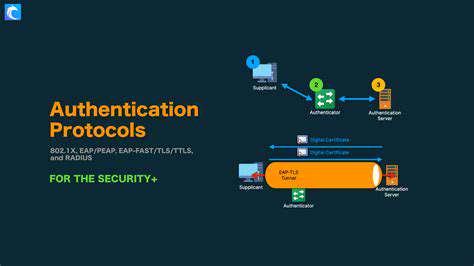

Security Considerations for IIoT Systems

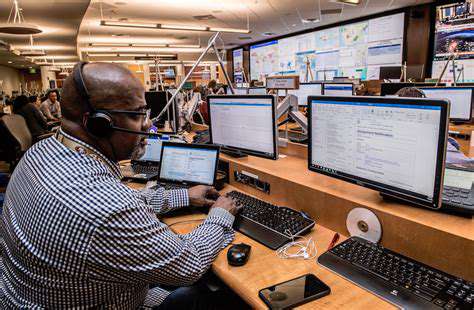

As IIoT ecosystems expand in complexity, they present broader attack surfaces for potential threats. Vulnerabilities in industrial control infrastructure can have catastrophic consequences affecting production continuity, workplace safety, and even national security interests. Implementing layered security defenses—including advanced encryption, granular access controls, and intelligent monitoring systems—is essential for protecting critical industrial assets.

Routine security audits, vulnerability scanning, and penetration testing help identify and remediate weaknesses before exploitation. Equally vital are continuous training programs that address the human element in cybersecurity.

The Impact of Artificial Intelligence on IIoT

Artificial intelligence is revolutionizing industrial IoT through predictive maintenance capabilities, production optimization, and task automation. AI-driven analytics can process vast sensor datasets to identify failure patterns and predict equipment issues before they occur, enabling proactive maintenance strategies. AI-powered predictive maintenance significantly reduces unplanned downtime while improving overall equipment efficiency metrics.

Beyond maintenance, AI algorithms can analyze production workflows to identify inefficiencies and recommend process improvements, leading to increased output and reduced operational waste.

Data Analytics and Business Intelligence in IIoT

The exponential growth of IIoT-generated data necessitates advanced analytical tools. Sophisticated data analysis provides actionable operational insights, enabling organizations to optimize processes and make evidence-based business decisions.

Modern business intelligence platforms transform complex operational data into intuitive visualizations, offering real-time visibility into key performance metrics. This enhanced transparency enables rapid response to emerging operational challenges.

The Role of 5G and Other Emerging Technologies

5G network capabilities are poised to significantly enhance IIoT implementations through increased bandwidth and reduced latency. The high-speed connectivity enabled by 5G facilitates real-time device communication and data exchange. This technological advancement will enable more sophisticated IIoT applications and use cases across industrial environments.

Concurrent developments in cloud computing and the Internet of Everything (IoE) are further expanding IIoT capabilities, creating new opportunities for industrial innovation and automation.

Future Skills and Workforce Development

The growing complexity of IIoT systems creates demand for professionals with expertise in cybersecurity, data science, and artificial intelligence. Comprehensive workforce development programs are essential for equipping current and future employees with the technical competencies required to manage advanced industrial systems.

Educational institutions must evolve their programs to address these emerging skill requirements, providing practical, industry-relevant training in IIoT technologies to cultivate the next generation of industrial technology professionals.

The Future of Industrial Automation

Industrial automation continues to evolve in parallel with IIoT advancements. The integration of these technologies will yield increasingly intelligent, autonomous production systems with unprecedented levels of connectivity.

This technological convergence promises significant improvements in operational efficiency, cost reduction, and workplace safety. The ongoing development of IIoT will continue to reshape industrial processes and manufacturing methodologies in transformative ways.