Precision Assembly Techniques

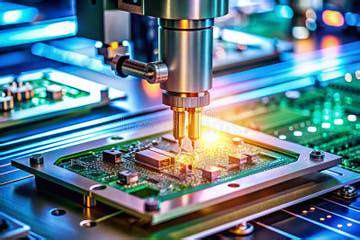

Precision assembly, a critical aspect of modern manufacturing, involves the meticulous joining of components with exacting tolerances. This process requires a high level of skill and specialized tools to ensure the components fit correctly and maintain the desired functionality. Careful consideration must be given to the materials used and the assembly procedures to prevent potential issues like misalignment, stress concentrations, or premature wear. Precise measurements and quality control protocols are paramount to achieve the desired outcomes.

Different assembly methods, such as mechanical fastening, adhesive bonding, or welding, each have their own advantages and limitations. Understanding these nuances is essential for selecting the most appropriate technique for a particular application. Furthermore, the use of automated assembly systems can enhance efficiency and consistency, leading to improved product quality and reduced production time.

Handling Components with Care

Proper component handling is just as important as the assembly process itself. Mishandling can lead to damage, contamination, or misalignment, ultimately affecting the final product's performance and reliability. Careful attention to detail in handling delicate components, especially those with intricate geometries or high-precision features, is essential. Using appropriate protective packaging and handling techniques is crucial to prevent scratching, dents, or other forms of damage.

The use of specialized tools and equipment, such as vacuum handling systems or robotic arms, can help to maintain consistent and gentle handling of components. These measures are particularly important in assembly lines where components are transferred from one stage to another frequently. Minimizing any potential for damage during transport and manipulation is crucial to maintaining the quality of the final product.

Environmental Control in Assembly

Maintaining a controlled environment during assembly is critical for ensuring the quality and consistency of the final product. Fluctuations in temperature, humidity, or even air pressure can significantly impact the accuracy of assembly processes. Precise temperature and humidity control are essential for maintaining the stability of materials and preventing variations in tolerances. Environmental contaminants like dust, particulates, or corrosive vapors can compromise the integrity of components and assembly procedures.

Quality Control and Inspection

Rigorous quality control and inspection procedures are essential for ensuring the precision and reliability of the final product. Regular checks and measurements at various stages of assembly are necessary to detect any deviations from the specified tolerances. Careful documentation of these inspections is vital for traceability and problem resolution. Implementing stringent quality assurance measures can significantly reduce the risk of defects and ensure the long-term performance of the assembled product. Robust quality control procedures are not merely a step but a crucial element in maintaining product integrity and customer satisfaction.

Enhanced Quality Control and Inspection: Robotic Eyes in the Sky

Enhanced Inspection Procedures

Implementing robust inspection procedures is crucial for maintaining high product quality. These procedures should be standardized, documented, and regularly reviewed to ensure their effectiveness. Thorough visual inspections are essential, looking for defects such as scratches, dents, or inconsistencies in color or texture. Furthermore, using advanced metrology tools for precise measurements can help identify subtle variations that might otherwise go unnoticed. This proactive approach minimizes the likelihood of faulty products reaching the market.

Rigorous testing protocols should be in place to verify the functionality and performance of each product. This includes comprehensive electrical and mechanical tests, ensuring every component operates as intended. Regular calibration of testing equipment is critical to maintain accuracy and reliability of the results. This continuous focus on quality control is a cornerstone of maintaining a high reputation.

Improved Supplier Collaboration

Stronger relationships with suppliers are paramount for achieving consistent quality. Open communication channels and regular meetings are vital to ensure alignment on quality standards and expectations. Joint quality audits can identify potential issues early on, fostering a collaborative approach to problem-solving. This collaborative effort ensures the supply chain is optimized for quality.

Establishing clear performance metrics for suppliers is key to driving continuous improvement. Regular feedback and performance reviews help suppliers understand expectations and adjust their processes accordingly. This proactive approach builds trust and fosters a sense of shared responsibility for quality.

Advanced Data Analysis Techniques

Leveraging advanced data analysis tools can provide valuable insights into product quality trends. Analyzing historical inspection data can help identify recurring issues and patterns. This allows for targeted interventions to address specific problems and prevent future occurrences. By understanding the root causes of defects, we can implement preventative measures to significantly reduce the number of faulty products.

Implementing statistical process control (SPC) methodologies is an effective way to track and analyze process variations. SPC charts provide visual representations of process data, allowing for quick identification of deviations from the norm. This detailed analysis allows for proactive responses, minimizing the impact of potential quality issues.

Investment in Training and Development

Investing in comprehensive training programs for quality control personnel is essential for maintaining a high level of expertise. Training should cover the latest inspection techniques, data analysis methods, and problem-solving strategies. This ensures employees are equipped with the necessary tools and knowledge to effectively identify and address quality issues. Ongoing professional development programs will also help employees stay abreast of industry best practices.

Implementing Quality Management Systems

The implementation of a robust quality management system (QMS) is crucial for standardizing processes and ensuring consistent quality across all aspects of production. A well-defined QMS outlines clear procedures for quality control, documentation, and corrective actions. This comprehensive approach ensures that everyone in the organization understands and adheres to quality standards, ultimately leading to a higher level of quality.

A QMS also fosters a culture of quality awareness and responsibility, encouraging employees at all levels to actively participate in maintaining high standards. This will also help meet customer expectations and achieve higher satisfaction. This detailed approach to quality management is a cornerstone of maintaining a strong reputation and ensuring customer satisfaction.

Customer Feedback and Continuous Improvement

Actively seeking and analyzing customer feedback is vital for identifying areas for improvement in product quality. Customer surveys, feedback forms, and direct communication channels can provide valuable insights into customer experiences and perceptions of the products. This feedback is crucial in pinpointing specific areas where improvements can be made to better meet customer needs and expectations. By listening to our customers, we can develop a better understanding of their needs and refine our products accordingly.

A culture of continuous improvement is essential for long-term success in quality control. This requires a commitment to regularly reviewing processes, identifying areas for optimization, and implementing changes to enhance efficiency and quality. This approach allows for adaptation to changing market demands and customer preferences.