The Future of Aerospace Supply Chain Visibility

Optimizing Global Logistics

The aerospace industry, characterized by intricate supply chains spanning continents, faces significant challenges in optimizing global logistics. Streamlining these complex networks is crucial for maintaining competitiveness and ensuring timely delivery of vital components. This necessitates exploring innovative solutions, such as predictive analytics and AI-powered routing algorithms, to anticipate and mitigate potential disruptions. Improved communication and collaboration among stakeholders are also essential for fostering agility and resilience within the system.

Implementing robust inventory management systems that account for fluctuating demand and potential delays is paramount. This involves leveraging data analytics to forecast future needs and proactively adjust stock levels, reducing the risk of shortages or excess inventory. By embracing these strategies, aerospace companies can significantly reduce operational costs and enhance overall efficiency.

Advanced Manufacturing Technologies

The future of aerospace supply chains is inextricably linked to the adoption of advanced manufacturing technologies. Additive manufacturing, or 3D printing, is poised to revolutionize component production, enabling the creation of complex, customized parts with reduced lead times and material waste. This technology allows for greater flexibility and responsiveness to changing design requirements. It also opens doors for decentralized manufacturing hubs, potentially reducing transportation costs and minimizing logistical complexities.

Advanced robotics and automation will play a crucial role in streamlining manufacturing processes. These technologies can handle repetitive tasks, ensuring higher precision and consistency in production. This will not only improve the quality of components but also free up human workers for higher-level tasks.

Sustainable Practices

Sustainability is no longer a fringe concern but a central tenet of modern aerospace supply chains. Companies are increasingly pressured to minimize their environmental footprint throughout the entire lifecycle of products. This includes reducing carbon emissions from transportation, adopting eco-friendly materials, and optimizing energy consumption in manufacturing facilities. Implementing robust environmental management systems is crucial for achieving sustainability goals.

Furthermore, the adoption of circular economy principles is vital. This involves designing products for disassembly and reuse, maximizing the lifespan of components, and recovering valuable materials at the end of their service life. These practices not only reduce waste but also contribute to a more responsible and environmentally conscious industry.

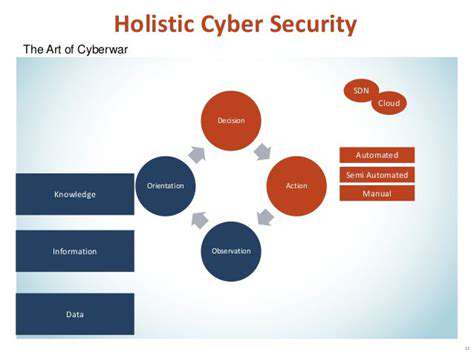

Data Analytics and AI Integration

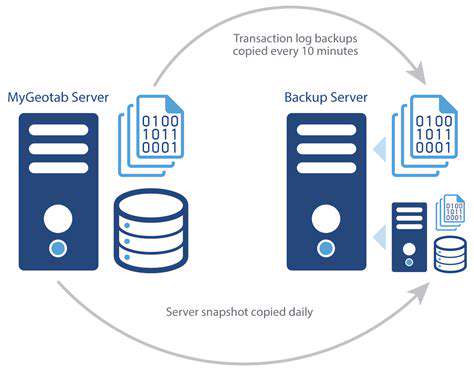

Data analytics and artificial intelligence (AI) are transforming the way aerospace supply chains operate. By harnessing the power of data, companies can gain deeper insights into their operations, enabling them to anticipate potential disruptions and optimize resource allocation. Real-time monitoring of inventory levels, transportation routes, and production processes allows for proactive intervention and swift adjustments in response to changing circumstances. Leveraging AI algorithms will enhance predictive capabilities, enabling companies to proactively address potential bottlenecks and optimize resource utilization.

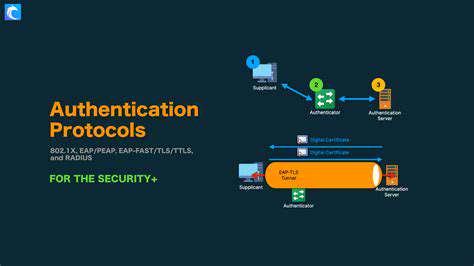

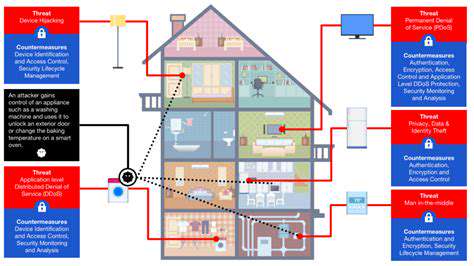

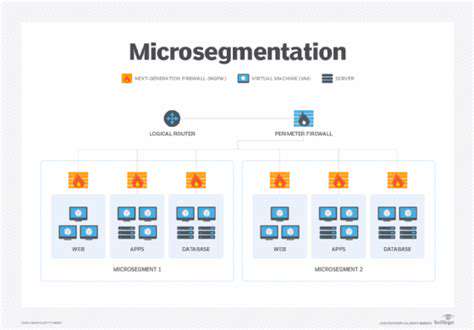

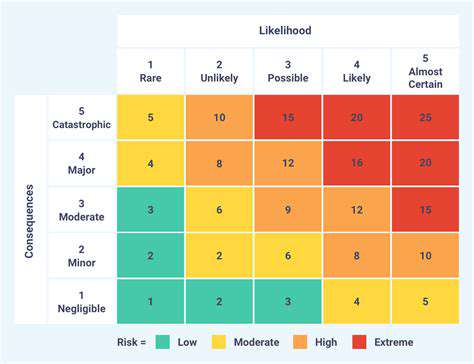

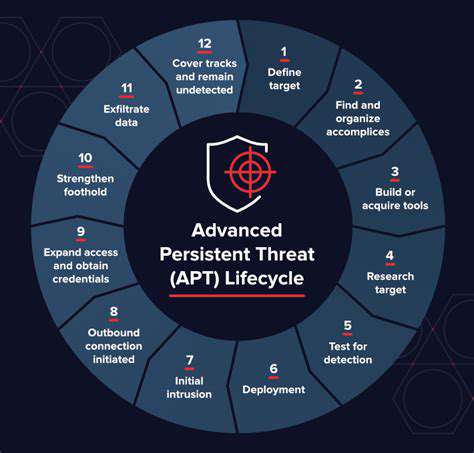

Cybersecurity Considerations

With the increasing reliance on digital systems, cybersecurity is a critical consideration in aerospace supply chains. Protecting sensitive data and preventing malicious attacks is paramount to maintaining operational integrity and preventing disruptions. Robust security protocols and regular security audits are essential for mitigating risks and safeguarding sensitive information. This includes encrypting data, implementing multi-factor authentication, and regularly updating software to address vulnerabilities. Robust cybersecurity measures are vital for maintaining the integrity and reliability of the aerospace supply chain.

Collaboration and Partnerships

Effective collaboration and strategic partnerships are essential for navigating the complexities of modern aerospace supply chains. Collaborating with suppliers, manufacturers, and logistics providers allows for the sharing of best practices, knowledge, and resources, fostering a collaborative environment. This fosters agility and resilience, allowing companies to adapt quickly to changing market demands and unforeseen challenges. Stronger relationships with stakeholders can also lead to innovations in supply chain management, increasing efficiency and responsiveness. Partnering with other companies that are experts in specific areas of supply chain management allows for a division of labor and a pooling of resources to achieve greater efficiency and effectiveness.