Predictive maintenance (PdM) is revolutionizing industrial operations by moving beyond reactive repairs to proactive maintenance strategies. This shift allows businesses to anticipate equipment failures before they occur, minimizing downtime and maximizing operational efficiency. PdM leverages data analytics and sophisticated algorithms to predict potential equipment issues, enabling timely interventions and preventing costly breakdowns.

By proactively addressing potential problems, organizations can significantly reduce maintenance costs and improve overall equipment effectiveness (OEE). This approach also enhances safety by preventing unexpected equipment failures that could lead to accidents or injuries.

Data Collection and Analysis: The Foundation of PdM

A crucial aspect of predictive maintenance is the robust collection and analysis of data. This involves gathering data from various sources, such as sensors, machine logs, and operational records. Sophisticated data analytics tools are then employed to identify patterns, anomalies, and trends that indicate potential equipment failures.

Machine Learning Algorithms: Empowering Predictions

Machine learning algorithms play a vital role in predictive maintenance by identifying complex relationships within the collected data. These algorithms can learn from historical data to predict future equipment performance and identify potential failures with high accuracy.

Machine learning's ability to learn and adapt is crucial for adapting to evolving equipment behavior and improving the accuracy of predictions over time.

Real-Time Monitoring and Alerting: Proactive Responses

Predictive maintenance systems often incorporate real-time monitoring capabilities, providing constant vigilance over equipment performance. This real-time data stream allows for immediate identification of anomalies, enabling swift interventions and preventing catastrophic equipment failures.

Prompt alerts allow maintenance teams to address issues before they escalate, minimizing downtime and ensuring optimal operational efficiency.

Enhanced Equipment Reliability and Safety

By anticipating potential equipment failures, predictive maintenance significantly enhances equipment reliability. This proactive approach minimizes unplanned downtime, enabling businesses to maintain consistent production levels and meet operational targets. Furthermore, avoiding sudden equipment failures directly contributes to a safer work environment.

Cost Savings and Optimized Resource Allocation

Predictive maintenance systems contribute significantly to cost savings by reducing unplanned downtime and maintenance expenses. By implementing this strategy, businesses can allocate resources more efficiently, focusing on proactive maintenance instead of reactive repairs. This allows for a more focused and strategic approach to maintenance.

Improved Operational Efficiency and Business Outcomes

The overall outcome of implementing predictive maintenance is improved operational efficiency and enhanced business outcomes. By minimizing downtime and maximizing equipment uptime, businesses can increase production output, improve quality, and ultimately enhance profitability. Predictive maintenance systems are instrumental in achieving these goals.

Predictive maintenance is not just about saving money; it's about optimizing processes and improving overall business performance.

AI-Driven Automation in Manufacturing and Assembly

AI-Powered Process Optimization

AI algorithms can analyze vast amounts of data from manufacturing processes, identifying inefficiencies and bottlenecks that might otherwise go unnoticed. This allows for the optimization of workflows, reducing production time, and minimizing waste. By learning from historical data and real-time feedback, AI systems can dynamically adjust parameters and optimize equipment performance, maximizing output and efficiency. This leads to significant cost savings and increased productivity in aerospace manufacturing.

Predictive maintenance capabilities are a key benefit of AI in this area. AI can analyze sensor data from machinery to anticipate potential failures before they occur, enabling proactive maintenance schedules. This reduces downtime, prevents costly repairs, and ensures consistent production output. The application of AI in aerospace manufacturing goes far beyond simply automating tasks; it fundamentally reshapes the entire production process.

Enhanced Quality Control

AI-powered vision systems can inspect parts with unparalleled precision, detecting defects and inconsistencies that might be missed by human inspectors. This enhanced quality control leads to fewer faulty products, reducing the need for costly rework and ensuring that aerospace components meet the highest standards of quality and safety. These systems can identify minute imperfections that are difficult or impossible for the human eye to discern, resulting in a significant improvement in overall product quality and reliability.

Intelligent Robotics and Assembly

AI is transforming the way robots perform assembly tasks. By integrating AI with robotic arms, manufacturers can create more flexible and adaptable assembly lines. These systems can learn complex assembly procedures, adjust to variations in part sizes and orientations, and even adapt to new product designs without extensive reprogramming. This allows for greater customization and responsiveness to changing demands in the aerospace industry.

Predictive Maintenance and Proactive Repair

AI excels at analyzing sensor data from machinery to identify patterns and anomalies that indicate potential failures. This allows manufacturers to schedule maintenance proactively, minimizing downtime and preventing costly breakdowns. The ability to predict equipment failures is crucial in aerospace manufacturing, where safety and reliability are paramount. By proactively addressing potential issues, AI helps to maintain consistent production output and ensures the safety of the entire operation.

Improved Supply Chain Management

AI can optimize the entire supply chain, from raw material procurement to finished product delivery. By analyzing data from various sources, AI systems can identify potential bottlenecks, predict demand fluctuations, and optimize inventory levels. This leads to reduced costs, improved delivery times, and enhanced responsiveness to changing market demands. In the aerospace industry, this is critical for maintaining the flow of parts and ensuring timely project completion.

Data-Driven Decision Making

AI systems collect and analyze vast amounts of data from various sources within the manufacturing process. This data provides valuable insights into production efficiency, quality control, and overall performance. By leveraging these insights, manufacturers can make data-driven decisions to optimize processes, reduce costs, and improve overall profitability. This data-driven approach is essential for making informed decisions and staying competitive in the dynamic aerospace industry. AI allows for a deeper understanding of the intricate relationships within the manufacturing process.

The Future of AI in Aerospace: Collaboration and Integration

The Rise of Autonomous Systems

Autonomous systems are poised to revolutionize aerospace, automating tasks that were previously handled by pilots and ground crews. This automation promises significant efficiency gains, reducing operational costs and increasing safety through precise, consistent execution. Imagine aircraft capable of navigating complex airspace without human intervention, potentially leading to reduced pilot workload and improved fuel efficiency. These advancements represent a paradigm shift in how we approach air travel, promising a future of more efficient, reliable, and potentially safer air travel.

Furthermore, the development of advanced algorithms for autonomous navigation and decision-making is critical. Such algorithms need to be robust enough to handle unexpected situations and unpredictable environmental factors, like extreme weather conditions, ensuring a high degree of safety and reliability in all operational scenarios.

Enhanced Aircraft Design and Performance

AI algorithms can analyze vast amounts of data to optimize aircraft design, leading to more aerodynamic shapes and lighter materials. This optimization translates into improved fuel efficiency and reduced emissions, a crucial aspect in the pursuit of sustainable aviation.

By utilizing AI-powered simulations and modeling, engineers can identify potential weaknesses in aircraft designs before they are built, leading to a safer and more reliable product. These insights allow for continuous improvement and the development of innovative solutions to address current design challenges, ensuring that aerospace remains at the forefront of technological advancement.

Predictive Maintenance and Safety

AI can predict potential maintenance needs, allowing for proactive interventions. This approach reduces unplanned downtime and avoids costly repairs, which is crucial in ensuring the safety and reliability of aircraft. Predictive maintenance also plays a vital role in optimizing the entire maintenance schedule, ensuring aircraft are operating at peak performance.

Personalized Flight Experiences

Imagine a future where flight experiences are tailored to individual preferences, from personalized cabin environments to optimized route planning based on real-time data. AI could provide insights into passenger needs and preferences, enabling airlines to offer a more customized and engaging travel experience.

Improved Air Traffic Management

AI can optimize air traffic control systems, improving efficiency and reducing delays. This translates into better utilization of airspace and reduced congestion, leading to smoother and more punctual flights.

Space Exploration and Discovery

AI's role in space exploration is equally significant, enabling autonomous spacecraft navigation, data analysis, and resource management on other planets. This technology opens up new frontiers in space exploration, allowing us to understand our universe in unprecedented detail. AI-powered robots can perform tasks that are too dangerous or difficult for humans, expanding the scope of space missions and accelerating the pace of scientific discovery.

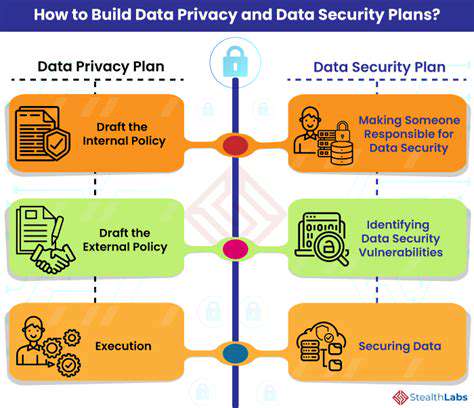

Cybersecurity and Data Privacy

As AI systems become more integrated into aerospace, robust cybersecurity measures are paramount. Protecting sensitive data and ensuring the integrity of AI systems is critical to preventing malicious attacks and maintaining the safety and reliability of aerospace operations. Implementing sophisticated security protocols and continuously monitoring systems for vulnerabilities will be crucial to safeguarding future aerospace technologies.