Introduction to Microgravity's Influence on Material Behavior

Understanding Microgravity

Microgravity is a state where the apparent weight of an object is significantly reduced, often described as a near-absence of gravity. This phenomenon occurs when an object is in freefall, experiencing a continuous acceleration towards a central point. In this state, objects appear to float, a stark contrast to our everyday experience on Earth where gravity exerts a constant downward force.

The Effects on the Human Body

Prolonged exposure to microgravity can have profound effects on the human body, including bone density loss and muscle atrophy. The lack of stress on bones due to weightlessness causes calcium to be reabsorbed into the body, weakening the skeletal structure. Simultaneously, the reduction in muscle use leads to a decrease in muscle mass and strength.

The cardiovascular system also experiences changes, with a redistribution of blood flow and a potential decrease in blood volume. These effects are not necessarily detrimental in short-term exposure, but can become significant concerns with extended stays in space.

Microgravity's Impact on Fluids and Liquids

In microgravity, fluids and liquids behave differently than on Earth. Instead of settling to the lowest point, they tend to float and distribute more uniformly. This unusual behavior is due to the absence of a gravitational force to pull them down. This is a crucial aspect of fluid dynamics and has implications for both scientific research and practical applications, like the design of spacecraft systems.

The Influence on Plant Growth

Plants, too, exhibit unique growth patterns in microgravity environments. The lack of gravity disrupts the normal directional cues that plants typically rely on for growth, leading to unusual shapes and orientations. This presents both challenges and opportunities for scientific exploration, offering insights into fundamental biological processes and potentially aiding in the development of novel agricultural techniques.

Challenges in Microgravity Research

Conducting scientific research in microgravity environments presents unique challenges. The cost of space travel and the complexities of maintaining a controlled laboratory environment are significant obstacles. Additionally, the limitations in conducting experiments and the difficulties in observing and analyzing results add further layers of complexity.

Applications and Potential Benefits

Despite the challenges, the study of microgravity has yielded significant benefits and opened up exciting possibilities for various fields. The insights gained from microgravity research are applicable to various fields, including materials science, biotechnology, and medicine. Furthermore, understanding microgravity has implications for future space exploration and the potential for establishing sustainable human settlements beyond Earth.

Future Directions

Future research in microgravity is likely to focus on mitigating the negative effects of prolonged exposure on the human body and developing strategies for counteracting bone and muscle loss. Furthermore, the exploration of innovative techniques for conducting experiments and managing resources in space will be paramount to expanding our understanding of this unique environment and its potential applications.

Material Processing and Manufacturing in Space

Material Selection and Characterization

A crucial aspect of material processing and manufacturing is the careful selection of the appropriate material for a specific application. This involves considering various factors, including mechanical properties like strength and ductility, thermal properties like melting point and conductivity, and chemical properties such as corrosion resistance. Understanding the material's behavior under different conditions is paramount to ensuring successful processing and manufacturing outcomes. Thorough material characterization, including techniques like tensile testing, hardness measurements, and chemical analysis, is essential to validate the chosen material's suitability and predict its performance in the intended application.

Furthermore, the selection process should take into account the availability, cost, and environmental impact of the material. Sustainable practices are increasingly important in material selection, driving the need for materials with lower environmental footprints. This includes recycled materials and materials derived from renewable resources. Proper characterization ensures the material's properties meet the desired specifications for the end product.

Processing Techniques

Numerous processing techniques are employed in material manufacturing, each with its advantages and limitations. These techniques can range from traditional methods like casting and forging to advanced methods like 3D printing and additive manufacturing. The choice of processing technique significantly impacts the final properties and microstructure of the material, influencing factors like grain size, defects, and overall quality. Selecting the right technique is crucial for achieving the desired product characteristics.

Different processing methods introduce various levels of control over the microstructure and properties of the material. Understanding these relationships is essential for optimizing the processing parameters and achieving desired outcomes. For instance, controlling the cooling rate during casting can significantly alter the final grain size and mechanical properties of the metal. This highlights the importance of meticulous process control in the manufacturing process.

Quality Control and Inspection

Implementing robust quality control and inspection procedures is vital for ensuring the reliability and consistency of manufactured products. This involves various methods for evaluating the physical, chemical, and mechanical properties of the material and the finished product. Testing procedures can include dimensional measurements, material analysis, and performance testing to ensure the product meets the required specifications. Consistent quality control measures prevent defects and ensure the product's usability and safety.

Quality control is not just about detecting defects; it's also about preventing them. Implementing quality control procedures at different stages of the manufacturing process can significantly reduce the risk of defects. This proactive approach ensures consistent product quality and reduces the need for costly rework or replacements. Implementing stringent quality standards is a key element for the long-term success of a manufacturing operation.

Manufacturing Processes and Equipment

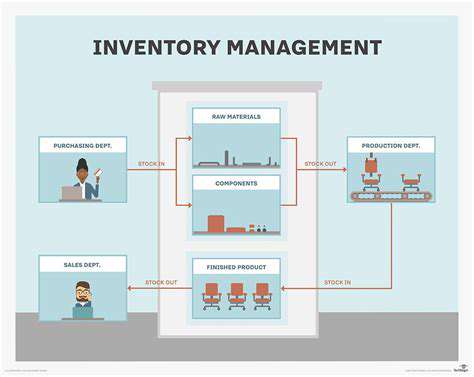

The manufacturing process itself encompasses a wide range of activities, from raw material preparation to final product packaging. The specific steps and equipment employed depend on the chosen material and the desired product characteristics. Different manufacturing processes require unique equipment and infrastructure. From specialized furnaces for heat treatment to advanced machining centers for precision components, the right equipment is critical for efficient and effective production. Understanding the intricacies of these processes and the capabilities of the equipment is crucial for optimizing the entire manufacturing workflow.

Effective utilization of the chosen equipment and processes is crucial for achieving optimal production rates and minimizing waste. This includes the selection of appropriate tooling, the optimization of process parameters, and the implementation of maintenance protocols. Implementing these strategies yields increased efficiency and cost savings in the long run.