The Intriguing Advantages of Orbital Production

Harnessing Microgravity for Superior Drug Formulation

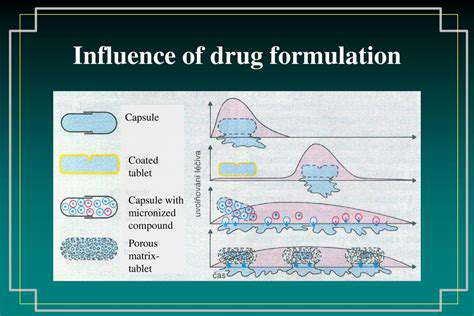

Microgravity environments, unique to orbital platforms, offer unprecedented opportunities for manipulating materials at a molecular level. This allows for the creation of drug formulations with enhanced stability, bioavailability, and targeted delivery. The absence of terrestrial gravity eliminates sedimentation and convection, enabling precise control over particle size and distribution, leading to more uniform and effective drug dispersal within the body. These advantages translate into potentially more potent and less toxic medications, impacting patient outcomes significantly.

Imagine a world where the production of life-saving pharmaceuticals is optimized for maximum efficacy. Orbital manufacturing, leveraging the unique characteristics of microgravity, could revolutionize this process. The ability to precisely control the formation of nanoparticles, for example, opens doors to novel drug delivery systems, potentially eliminating the need for invasive procedures and maximizing the effectiveness of existing treatments.

Reduced Contamination and Enhanced Purity

Manufacturing pharmaceuticals in space offers a significant advantage in minimizing contamination. The absence of terrestrial environmental factors, such as dust, microorganisms, and airborne particles, creates a pristine manufacturing environment. This leads to a higher purity of the final product, crucial for minimizing side effects and maximizing efficacy. The controlled environment of space-based facilities allows for greater precision and consistency in the production process, ultimately resulting in more reliable and safe medications.

Traditional pharmaceutical manufacturing on Earth faces challenges related to contamination and cross-contamination. This can compromise product quality and safety. The isolated and controlled environment of space manufacturing offers a solution, significantly improving the overall purity and safety of the drugs produced. This is critical for ensuring the efficacy and minimizing potential harm to patients.

Optimized Resource Utilization and Cost Savings

Orbital production of pharmaceuticals can be more efficient in terms of resource usage. Reduced transportation costs and minimized waste generation are key factors. The ability to source raw materials directly from space-based resources, such as asteroids or lunar regolith, further enhances the potential for cost-effectiveness. This could lead to the development of novel and affordable medications for global populations, especially in underserved areas.

By eliminating the need for extensive transportation networks and reducing the environmental impact of traditional manufacturing processes, space-based production could revolutionize the pharmaceutical industry's approach to resource utilization. The ability to manufacture drugs closer to where they are needed, with less waste, creates a more sustainable and cost-effective model for the future of medicine.

Scalability and Flexibility for Future Demands

Orbital manufacturing facilities can be designed with scalability in mind. Modular structures can be added or modified as production needs evolve. This adaptability allows for rapid response to emerging health crises and changing global demands. As the global population grows, and new diseases emerge, the capacity to rapidly increase or decrease production in response to these challenges is a critical advantage.

Accelerated Research and Development Cycles

The unique environment of space provides a platform for accelerated research and development of novel pharmaceuticals. Scientists can conduct experiments under controlled conditions, free from the constraints of terrestrial gravity and environmental factors. This leads to faster discoveries and the development of new therapies and treatments. Faster research cycles potentially translate to faster delivery of life-saving medicines to patients who need them most.

Imagine the potential for groundbreaking research into new drug delivery systems or innovative therapies for rare diseases. The unique conditions of space enable researchers to push the boundaries of scientific knowledge and rapidly translate those discoveries into effective treatments. This translates to improved patient outcomes and a faster pace of progress in the fight against various medical conditions.

Microgravity's Influence on Drug Formulation

Microgravity and Drug Delivery

Microgravity, the near-absence of gravity experienced in space, presents unique challenges and opportunities for drug formulation and delivery. Understanding how this environment affects drug behavior is crucial for developing effective and safe therapeutic strategies for astronauts and potentially for terrestrial applications.

The altered fluid dynamics and convection patterns in microgravity can significantly impact the dissolution and absorption of medications. This can lead to variations in drug bioavailability and efficacy compared to Earth-based conditions.

Effects on Drug Crystallization

The absence of buoyancy forces in microgravity can alter the conditions for drug crystallization. This can lead to the formation of different crystal structures, potentially affecting the drug's solubility, stability, and ultimately, its therapeutic effectiveness.

Different crystal forms may possess varying dissolution rates, impacting the rate at which the drug is released into the body. This can have significant implications for the timing and efficacy of drug action.

Impact on Formulation Stability

The absence of gravity can influence the stability of drug formulations. Changes in the behavior of excipients, or inactive components of a drug, can alter the integrity and performance of the drug product. This is a critical concern for long-duration space missions, where the stability of medications must be maintained for extended periods.

Maintaining the desired properties of the drug formulation under these unusual conditions is of utmost importance, and research is ongoing to develop suitable countermeasures.

Drug Absorption and Distribution

Drug absorption and distribution processes are often influenced by gravity on Earth. In microgravity, the altered fluid dynamics and convection patterns can affect the transport of drugs throughout the body, potentially impacting their efficacy and safety.

Understanding these changes is vital to designing effective drug delivery systems for space missions, minimizing potential adverse effects, and maximizing therapeutic benefit.

Challenges in Formulation Design

Developing drug formulations suitable for use in microgravity presents significant challenges. Researchers need to consider the unique effects of microgravity on drug behavior, including crystallization, stability, absorption, and distribution, to design formulations that maintain efficacy and safety.

The design of drug delivery systems and the selection of excipients must carefully account for the altered conditions in space. This requires extensive research and development efforts to create effective and reliable drug delivery methods for astronauts.

Potential for Novel Drug Delivery Systems

The unique environment of microgravity offers the potential for developing innovative drug delivery systems. Researchers are exploring novel approaches to drug targeting and release that might not be feasible in Earth-based conditions. This could lead to advancements in treatment strategies for a wide range of diseases.

Therapeutic Implications for Earth

The research conducted to address drug delivery challenges in microgravity may also have significant implications for terrestrial applications. Insights gained into drug behavior under altered conditions could lead to advancements in drug design, formulation, and delivery for various diseases on Earth. The knowledge gained in space may lead to improved drug therapies and reduced side effects for patients.

Understanding the intricate relationship between gravity, drug behavior, and drug delivery is paramount for both space exploration and terrestrial health.

Addressing Supply Chain Vulnerabilities

Space-Based Manufacturing for Enhanced Security

The inherent vulnerabilities of terrestrial supply chains, particularly in the pharmaceutical industry, are well-documented. Natural disasters, geopolitical instability, and even simple logistical bottlenecks can disrupt production and delivery, leading to shortages and potentially impacting public health. Moving pharmaceutical manufacturing into space offers a unique opportunity to mitigate these risks by establishing a geographically dispersed and resilient production system beyond the reach of terrestrial disruptions.

Reduced Dependency on Global Logistics

Pharmaceutical supply chains are often intricate and globally dispersed. This reliance on international shipping and handling creates a multitude of potential points of failure. A space-based manufacturing facility would reduce reliance on these complex and often vulnerable global logistics networks, providing a more secure and predictable means of production and delivery. This would lead to a more stable and reliable flow of pharmaceuticals, particularly in emergency situations.

Enhanced Resilience to Disruptions

Natural disasters, political instability, and even simple logistical issues can cripple terrestrial supply chains. Space-based manufacturing, operating in a stable and predictable environment, would be largely impervious to these kinds of disruptions. This enhanced resilience would be critical in ensuring the consistent supply of life-saving pharmaceuticals, regardless of events on Earth.

Potential for Faster Delivery Times

Eliminating terrestrial transportation bottlenecks and leveraging potentially faster transit times through space allows for significantly quicker delivery of pharmaceuticals to affected regions. This is particularly crucial in emergency situations where rapid response is essential for patient care. The speed of delivery would greatly enhance the effectiveness of pharmaceutical interventions.

Minimizing Counterfeiting and Tampering

Manufacturing in space, operating in a controlled environment, offers a higher degree of security against counterfeiting and tampering. The lack of direct access to the production facilities and the inherent difficulty of transporting large volumes of product from space to Earth dramatically reduces the possibility of illicit activities impacting the supply chain.

Cost Considerations and Scalability

While the initial investment for establishing space-based manufacturing facilities will likely be substantial, the long-term cost benefits of enhanced security, resilience, and efficiency could outweigh these initial expenses. The scalability of space-based manufacturing could ultimately lead to lower production costs and increased accessibility for pharmaceuticals in underserved regions.

Ethical Considerations and Accessibility

The potential benefits of space-based pharmaceutical manufacturing must be carefully balanced against ethical considerations, particularly concerning equitable access to life-saving medications. Ensuring that the technology and its benefits are accessible to all, regardless of geographical location or economic status, is essential to its responsible development and implementation.