Thermal Extraction Techniques: Introduction

Thermal extraction techniques are a crucial set of methods in various scientific and industrial applications, particularly in the fields of chemistry, material science, and environmental remediation. These techniques leverage heat to facilitate the separation and extraction of desired components from a sample. Understanding the principles behind these methods is essential for optimizing extraction efficiency and achieving accurate results. Choosing the appropriate technique depends on the specific sample properties, the desired component, and the overall experimental goals.

Solvent-Free Thermal Extraction

Solvent-free thermal extraction methods offer a significant advantage over solvent-based approaches by eliminating the use of volatile organic compounds (VOCs). This is important for minimizing environmental impact and health risks associated with solvent handling. These methods typically involve heating the sample under controlled conditions to promote the desired separation. The process can be tailored to specific materials and desired compounds, allowing for greater control over the extraction process.

For example, in the analysis of food products, solvent-free thermal extraction is preferred due to its safety and minimal impact on the original product's characteristics. It also allows for a more sustainable approach to product analysis.

Supercritical Fluid Extraction

Supercritical fluid extraction (SFE) is a powerful technique that utilizes supercritical fluids, such as carbon dioxide, to extract components from a sample. These fluids possess unique properties that allow for high selectivity and minimal sample degradation. This is achieved by adjusting pressure and temperature to control the fluid's density, which affects its ability to dissolve and extract target compounds. SFE is often preferred for sensitive materials, where the use of harsh solvents would be detrimental.

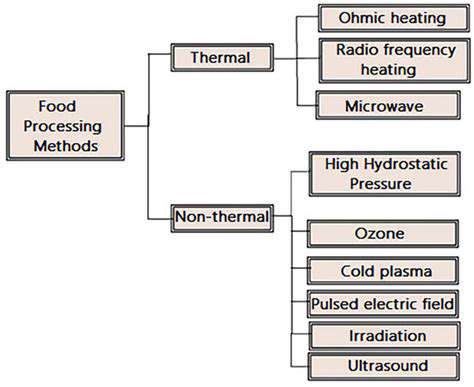

Microwave-Assisted Extraction

Microwave-assisted extraction (MAE) is a relatively rapid technique that utilizes electromagnetic radiation to heat the sample. This method typically offers higher extraction yields and shorter extraction times compared to conventional methods. The rapid heating allows for the efficient extraction of thermally sensitive compounds without significant degradation. The controlled heating is crucial in preserving the integrity of the extracted compounds.

Steam Distillation

Steam distillation is a versatile technique commonly used for the separation and purification of volatile components from a sample. It leverages the vapor pressure of water to carry the desired compounds into a separate phase, facilitating their collection and isolation. This method is particularly effective for separating volatile organic compounds and mixtures from solid matrices. This process is commonly used in the extraction of essential oils from plants.

Vacuum Extraction

Vacuum extraction techniques are used to improve the rate of extraction by reducing the pressure in the system. This reduction lowers the boiling point of the solvent, allowing for more efficient extraction, especially for compounds with high boiling points. The lower pressure environment can also minimize the degradation of heat-sensitive compounds. Vacuum extraction is particularly useful in applications where the sample contains components that are difficult to extract using conventional techniques. These techniques are widely used in various industries to extract valuable compounds for further analysis or processing.

Mechanical Extraction Methods: Breaking Down the Regolith

Mechanical Extraction Methods: Overview

Mechanical extraction methods for lunar ice focus on physically removing the ice from the regolith, the loose layer of dust and rock on the lunar surface. These methods generally involve a combination of techniques, including targeted excavation, selective material separation, and transport mechanisms. Understanding the unique properties of lunar regolith, like its low density and potential for high variability in ice content, is crucial for developing effective extraction strategies. Different extraction methods may be more suitable depending on the specific location and characteristics of the ice deposit.

The primary goal of mechanical extraction is to minimize contamination of the extracted ice. This involves careful design of tools and procedures to avoid introducing extraneous materials into the collected ice samples. Successful extraction also requires considering the complexities of lunar dust, which can adhere to equipment and potentially affect the purity of the harvested ice. Early research and testing in simulated lunar environments are critical to refine these methods for future missions.

Excavation Techniques: Creating Access to Ice

Various excavation techniques are being explored for accessing lunar ice deposits. These include the use of mechanical arms, drills, and potentially even specialized scoops designed to effectively penetrate and remove the regolith overlying the ice. The choice of excavation method will depend on the depth and density of the regolith layer, as well as the desired yield of extracted material. Careful consideration of the lunar environment, including the potential for dust storms and localized variations in terrain, is essential for optimizing the process.

Precise control over the excavation process is vital. Minimizing disturbance to the surrounding regolith and the ice deposit itself is critical to preserve the integrity of the ice and prevent contamination. Advanced robotics and remote operation would be essential for these tasks, allowing for precise targeting and controlled removal of material.

Selective Material Separation: Isolating the Ice

Once the regolith is excavated, separating the ice from the surrounding materials becomes a critical step. This often involves techniques like sieving and filtration, where the ice, due to its different physical properties, can be separated from the rocky and dusty components. The efficiency of these separation methods is vital to maximize the yield of pure ice and minimize the amount of waste material. The design of these separation systems must also account for the unique characteristics of lunar dust, including its tendency to adhere to other materials.

Transport Mechanisms: Moving the Extracted Ice

Efficient transport of the extracted ice from the excavation site to designated processing facilities is crucial for the overall extraction process. This involves the development of specialized containers and transport systems capable of withstanding the harsh lunar environment. These systems must be designed to prevent the ice from being damaged or contaminated during transit. Considerations such as temperature control and the avoidance of dust accumulation are paramount to maintaining the quality of the ice samples.

Waste Management: Addressing Lunar Dust and Debris

A key aspect of any mechanical extraction process is the management of waste materials. The regolith removed during excavation will need to be properly disposed of or potentially utilized in other lunar activities. Careful consideration must be given to the potential environmental impact of waste disposal on the lunar surface. Innovative solutions may involve utilizing the extracted regolith for construction materials, or storing it in designated areas to minimize its impact on future operations.

Future Considerations: Optimizing for Efficiency and Sustainability

Future research will likely focus on optimizing mechanical extraction methods for maximum efficiency and sustainability. This includes exploring the use of advanced materials and technologies for equipment durability and increased yield. Furthermore, the development of automated systems for remote operation and self-maintenance will contribute to reducing operational costs and risks. The long-term goal is to develop sustainable extraction techniques that minimize the environmental impact of lunar resource utilization.